end wall flashing detail

The roofing squares are locked into a 20 oz. The Type Of Screw Depends On The Material Of The Wall.

Eave Soffit Vent Google Search Construction Documents Metal Roof Construction Gutters

A bituminous coating or a strip of asphalt saturated felt.

. The sill flashing detail requires that a backer rod and sealant be applied below the flashing. If there is no metal flashing installed at the wall. Vertical Wall Flashing This detail shows a flashing condition at a vertical wall or parapet.

Key Flashing Details at Building Wall. Copper base flashing which extends at least 8 up the. Inspect the wall and roof framing to assess existing conditions and develop specific detailing for flashing the intersection of the wall and roof.

Using a pencil or a sharpie mark where the flashing and gable meet. 330 769-3546 Toll Free. Hyload Headquarters 5020 Enterprise Parkway Seville Ohio 44273 Email.

From any corner or end of wall. On center and a minimum of 10 ft. The purpose of a flashing is to make the building weather-resistant and to prevent water from entering the building by diverting it.

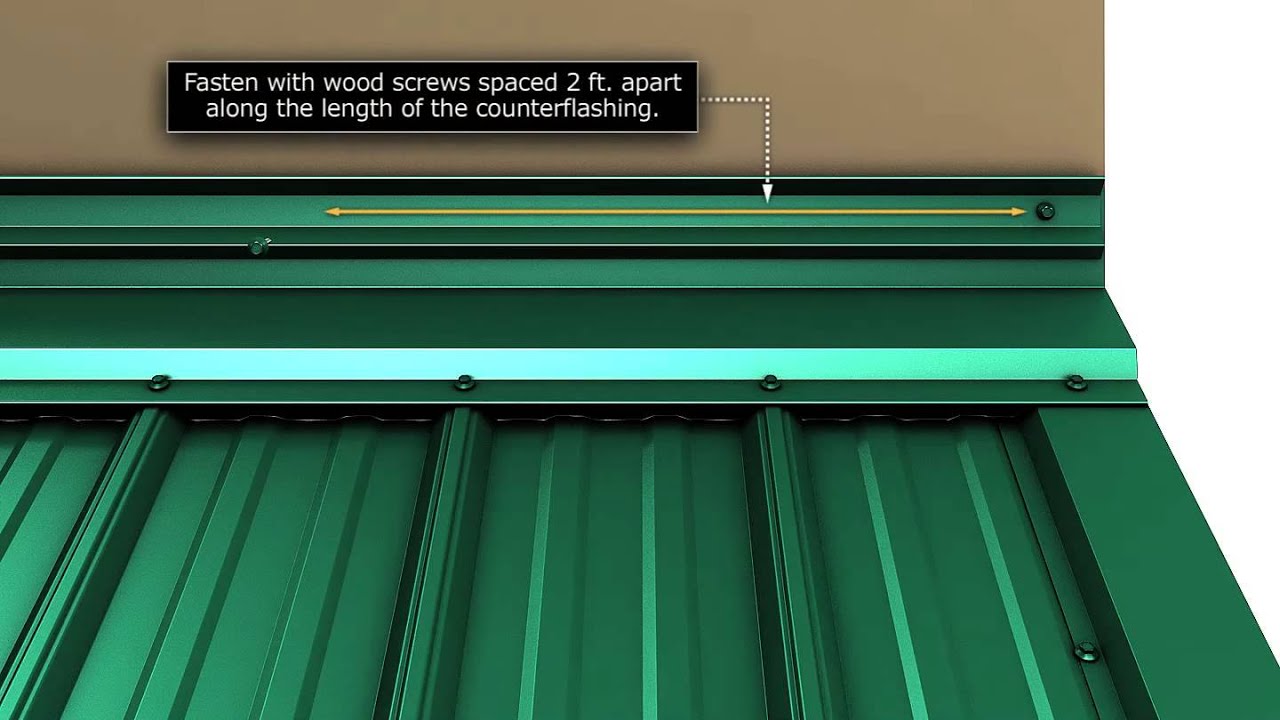

At the base of walls a sheet metal flashing assembly that extends from the face of the backup wall through the masonry should be used to form a drip outside the wall. ADD UP THE TOTAL LINEAR FEET. Endwall Flashing From 2420From 2057 10 Long Length 26 Gauge Metal Matches color of panel Use with OUTSIDE CLOSURES HOW MANY DO I NEED.

Flashing is generally fixed to cladding or other flashing sections using rivets or self-drilling screws. Now you will know where to place the Z-trim. Applying base flashing to a front wall where asphalt shingles meet the front wall siding For front end-walls where roofing shingles meet siding the metal flashing strip should.

Laps are heat-welded and the. From any corner or end of wall. Fasteners close to folded edges generally cause the least distortion.

It protects specific areas within exterior wall assemblies and creates an impervious barrier for water to follow to the face of the exterior. Then take the flashing off and. Leave approximately one inch past the edge of the gable trim on both ends of the flashing.

Flashings and cappings are strips of metal formed to. Endwall flashing is to be used where there is a lean-to type roof sloping away from the vertical wall. Plates and fasteners get installed at the seamvertically up the wall at 12 in.

The flashing must be dammed at the ends. Its placed behind the wall steel and on top of the roof steel. Through wall flashing is above grade waterproofing.

Black Metal Roof Porch Architecture Interior Design Guidelines

Pin By Silin He On Detail Expansion Joint Masonry The Expanse

Pitched Roof To Brick Wall Huse

Pin On Architectural Construction Details

Metal Roof Installation Metal Roof Standing Seam Metal Roof

How To Install Endwall Trim For Union S Masterrib Panel Metal Roof Installation Roof Installation Corrugated Metal Roof

02 010 0401 Sill Detail Single Wythe Block International Masonry Institute Masonry Roof Detail Roof Siding

Pin By End Studio On Porch Ideas Masonry Wall Shingling Roof Maintenance